| Availability: | |

|---|---|

| Quantity: | |

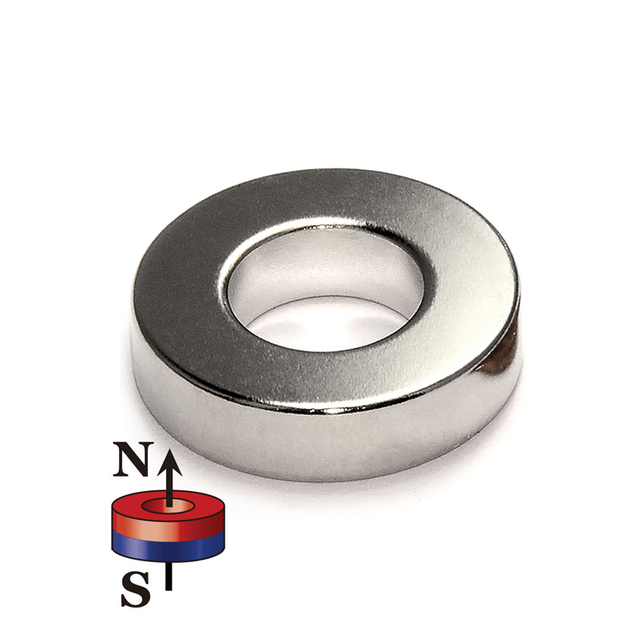

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~61℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | 125 piece neodymium magnet cube | Package | customized |

| Shape | magnetic disk 125 piece neodymium magnet cube | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.How do you demagnetize a Neodymium Magnet?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Neodymium magnets can be demagnetized by heating them to a temperature of around 200°C (392°F) for a few minutes. This will cause the magnet to lose its magnetic properties. It is also possible to demagnetize a neodymium magnet by exposing it to a strong alternating magnetic field.

2.Can 125 piece neodymium magnet cube damage credit cards or electronic devices?

Being one of the top 125 piece neodymium magnet cube manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

3.About 125 piece neodymium magnet cube quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

4.How do 125 piece neodymium magnet cube work?

We have established a good reputation and reliable partnerships within the 125 piece neodymium magnet cube industry. Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications. Neodymium magnets work by creating a strong magnetic field that attracts ferromagnetic materials, such as iron, nickel, and cobalt. The magnetic field is created when the electrons in the atoms of the neodymium alloy align in the same direction. This alignment creates a strong magnetic field that can attract ferromagnetic materials from a distance.

5.Can 125 piece neodymium magnet cube be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

6.About 125 piece neodymium magnet cube production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

7.Can 125 piece neodymium magnet cube lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

8.About 125 piece neodymium magnet cube production management system

Neodymium magnets production management system is a software solution designed to help manufacturers of neodymium magnets manage their production processes. The system provides a comprehensive set of tools to help streamline production, from tracking orders and inventory to managing quality control and production scheduling. It also provides detailed reporting and analytics to help manufacturers make informed decisions about their production processes. The system is designed to be user-friendly and intuitive, allowing users to quickly and easily access the information they need.

9.About 125 piece neodymium magnet cube customization services

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets can be customized to meet specific requirements, such as size, shape, and strength. Customization services can include machining, coating, and assembly. Customized neodymium magnets can be used in a variety of applications, including motors, sensors, and medical devices.

10.Are there any potential hazards associated with 125 piece neodymium magnet cube?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, there are potential hazards associated with neodymium magnets. They can be very powerful and can cause serious injury if swallowed. They can also pinch fingers and other body parts if two magnets are brought together too quickly. Additionally, neodymium magnets can interfere with pacemakers and other medical devices, and can damage electronic equipment if placed too close.

11.What is the weight-to-strength ratio of 125 piece neodymium magnet cube?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

12.Can 125 piece neodymium magnet cube be used for magnetic data storage?

No, neodymium magnets cannot be used for magnetic data storage. Neodymium magnets are too weak to store data reliably. Magnetic data storage requires much stronger magnets, such as rare earth magnets.

13.About 125 piece neodymium magnet cube origin

Neodymium magnets, also known as rare earth magnets, are the strongest type of permanent magnet available. They were first developed in the 1980s by General Motors and Sumitomo Special Metals. Neodymium magnets are composed of an alloy of neodymium, iron, and boron, and are used in a wide variety of applications, including motors, generators, hard drives, and speakers.

14.How are 125 piece neodymium magnet cube used in the military?

Neodymium magnets are used in the military for a variety of applications. They are used in navigation systems, guidance systems, and sensors. They are also used in weapons systems, such as magnetic mines, and in the guidance systems of missiles and torpedoes. Neodymium magnets are also used in the construction of military vehicles, such as tanks and aircraft, to reduce their weight and improve their performance.

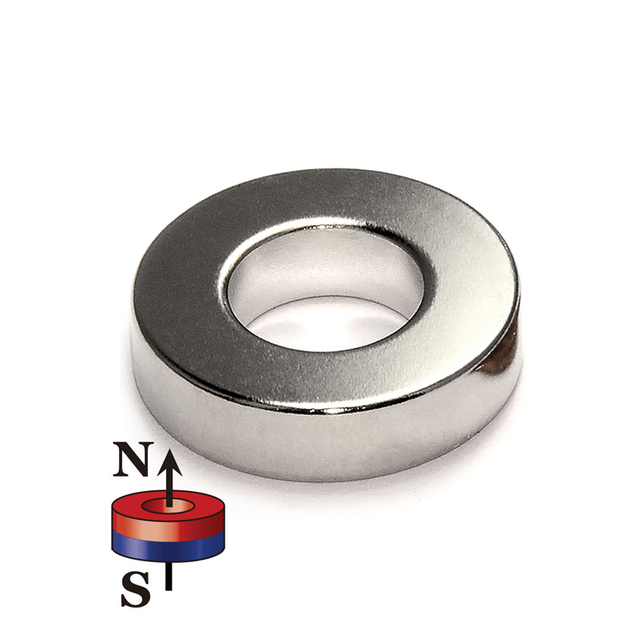

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~61℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | 125 piece neodymium magnet cube | Package | customized |

| Shape | magnetic disk 125 piece neodymium magnet cube | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.How do you demagnetize a Neodymium Magnet?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Neodymium magnets can be demagnetized by heating them to a temperature of around 200°C (392°F) for a few minutes. This will cause the magnet to lose its magnetic properties. It is also possible to demagnetize a neodymium magnet by exposing it to a strong alternating magnetic field.

2.Can 125 piece neodymium magnet cube damage credit cards or electronic devices?

Being one of the top 125 piece neodymium magnet cube manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

3.About 125 piece neodymium magnet cube quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

4.How do 125 piece neodymium magnet cube work?

We have established a good reputation and reliable partnerships within the 125 piece neodymium magnet cube industry. Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications. Neodymium magnets work by creating a strong magnetic field that attracts ferromagnetic materials, such as iron, nickel, and cobalt. The magnetic field is created when the electrons in the atoms of the neodymium alloy align in the same direction. This alignment creates a strong magnetic field that can attract ferromagnetic materials from a distance.

5.Can 125 piece neodymium magnet cube be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

6.About 125 piece neodymium magnet cube production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

7.Can 125 piece neodymium magnet cube lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

8.About 125 piece neodymium magnet cube production management system

Neodymium magnets production management system is a software solution designed to help manufacturers of neodymium magnets manage their production processes. The system provides a comprehensive set of tools to help streamline production, from tracking orders and inventory to managing quality control and production scheduling. It also provides detailed reporting and analytics to help manufacturers make informed decisions about their production processes. The system is designed to be user-friendly and intuitive, allowing users to quickly and easily access the information they need.

9.About 125 piece neodymium magnet cube customization services

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets can be customized to meet specific requirements, such as size, shape, and strength. Customization services can include machining, coating, and assembly. Customized neodymium magnets can be used in a variety of applications, including motors, sensors, and medical devices.

10.Are there any potential hazards associated with 125 piece neodymium magnet cube?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, there are potential hazards associated with neodymium magnets. They can be very powerful and can cause serious injury if swallowed. They can also pinch fingers and other body parts if two magnets are brought together too quickly. Additionally, neodymium magnets can interfere with pacemakers and other medical devices, and can damage electronic equipment if placed too close.

11.What is the weight-to-strength ratio of 125 piece neodymium magnet cube?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

12.Can 125 piece neodymium magnet cube be used for magnetic data storage?

No, neodymium magnets cannot be used for magnetic data storage. Neodymium magnets are too weak to store data reliably. Magnetic data storage requires much stronger magnets, such as rare earth magnets.

13.About 125 piece neodymium magnet cube origin

Neodymium magnets, also known as rare earth magnets, are the strongest type of permanent magnet available. They were first developed in the 1980s by General Motors and Sumitomo Special Metals. Neodymium magnets are composed of an alloy of neodymium, iron, and boron, and are used in a wide variety of applications, including motors, generators, hard drives, and speakers.

14.How are 125 piece neodymium magnet cube used in the military?

Neodymium magnets are used in the military for a variety of applications. They are used in navigation systems, guidance systems, and sensors. They are also used in weapons systems, such as magnetic mines, and in the guidance systems of missiles and torpedoes. Neodymium magnets are also used in the construction of military vehicles, such as tanks and aircraft, to reduce their weight and improve their performance.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.