| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~89℃ |

| Type | Permanent | Delivery time | 3-15days |

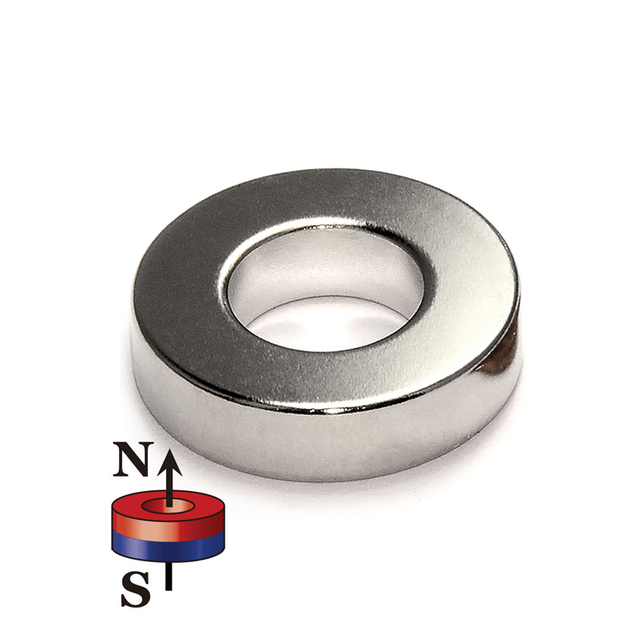

| Composite | 3 4 x 1 8 neodymium magnet | Package | customized |

| Shape | flat 3 4 x 1 8 neodymium magnet | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.About 3 4 x 1 8 neodymium magnet warranty

Neodymium magnets are generally covered by a one-year warranty against defects in materials and workmanship. The warranty does not cover damage caused by misuse, abuse, or improper handling. If a magnet is found to be defective, the manufacturer will replace it with a new one.

2.Are there any potential hazards associated with 3 4 x 1 8 neodymium magnet?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, there are potential hazards associated with neodymium magnets. They can be very powerful and can cause serious injury if swallowed. They can also pinch fingers and other body parts if two magnets are brought together too quickly. Additionally, neodymium magnets can interfere with pacemakers and other medical devices, and can damage electronic equipment if placed too close.

3.How do 3 4 x 1 8 neodymium magnet contribute to the aerospace industry?

Neodymium magnets are used in a variety of aerospace applications, including in electric motors, actuators, and sensors. They are also used in navigation systems, guidance systems, and propulsion systems. Neodymium magnets are highly resistant to corrosion and can withstand extreme temperatures, making them ideal for use in aerospace applications. Additionally, their high magnetic strength makes them ideal for use in motors and actuators, allowing for more efficient operation and greater power output.

4.What are the potential future advances in Neodymium Magnet technology?

1. Improved magnetization processes: Developing new methods to increase the magnetization of neodymium magnets, such as using high-frequency alternating current or pulsed direct current, could lead to stronger magnets. 2. Improved coating processes: Developing new methods to coat neodymium magnets with protective layers could help to reduce corrosion and improve the longevity of the magnets. 3. Improved manufacturing processes: Developing new methods to manufacture neodymium magnets more efficiently and cost-effectively could help to reduce the cost of the magnets. 4. Improved recycling processes: Developing new methods to recycle neodymium magnets could help to reduce the environmental impact of the magnets. 5. Improved magnetic field control: Developing new methods to control the magnetic field of neodymium magnets could help to improve the performance of the magnets in various applications.

5.Are 3 4 x 1 8 neodymium magnet used in headphones and speakers?

Our company has many years of 3 4 x 1 8 neodymium magnet experience and expertise. Yes, neodymium magnets are used in headphones and speakers. They are used to create a strong magnetic field that helps to produce a clear and powerful sound.

6.What is the maximum pulling force of a Neodymium Magnet?

We focus on innovation and continuous improvement to maintain a competitive advantage. The maximum pulling force of a Neodymium magnet depends on the size and shape of the magnet, but generally ranges from 10 to 200 pounds.

7.Can 3 4 x 1 8 neodymium magnet be used for magnetic therapy?

No, neodymium magnets are not recommended for use in magnetic therapy. Neodymium magnets are very powerful and can cause tissue damage if used incorrectly. It is best to consult a qualified healthcare professional before using any type of magnetic therapy.

8.About 3 4 x 1 8 neodymium magnet production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

9.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

10.Can 3 4 x 1 8 neodymium magnet be used in high-temperature environments?

Our 3 4 x 1 8 neodymium magnet products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

11.How do 3 4 x 1 8 neodymium magnet contribute to the transportation industry?

Neodymium magnets are used in a variety of transportation applications, including electric motors, generators, and brakes. They are used in electric vehicles to help reduce the weight of the vehicle and improve its efficiency. They are also used in hybrid and electric vehicles to help reduce the amount of energy needed to power the vehicle. Additionally, neodymium magnets are used in magnetic levitation trains, which use magnetic fields to lift and propel the train.

12.About 3 4 x 1 8 neodymium magnet origin

Neodymium magnets, also known as rare earth magnets, are the strongest type of permanent magnet available. They were first developed in the 1980s by General Motors and Sumitomo Special Metals. Neodymium magnets are composed of an alloy of neodymium, iron, and boron, and are used in a wide variety of applications, including motors, generators, hard drives, and speakers.

13.Can 3 4 x 1 8 neodymium magnet be used in underwater applications?

Our mission is to provide customers with the best solutions for 3 4 x 1 8 neodymium magnet. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

14.What is the magnetic field strength of a Neodymium Magnet?

The magnetic field strength of a Neodymium magnet can range from 10,000 to 14,000 gauss.

15.How do 3 4 x 1 8 neodymium magnet contribute to renewable energy sources?

Neodymium magnets are used in many renewable energy sources, such as wind turbines and solar panels. They are used to generate electricity from the rotation of the turbine blades or the movement of the sun’s rays. Neodymium magnets are also used in electric motors, which are used to power electric vehicles. Additionally, they are used in generators to convert mechanical energy into electrical energy.

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~89℃ |

| Type | Permanent | Delivery time | 3-15days |

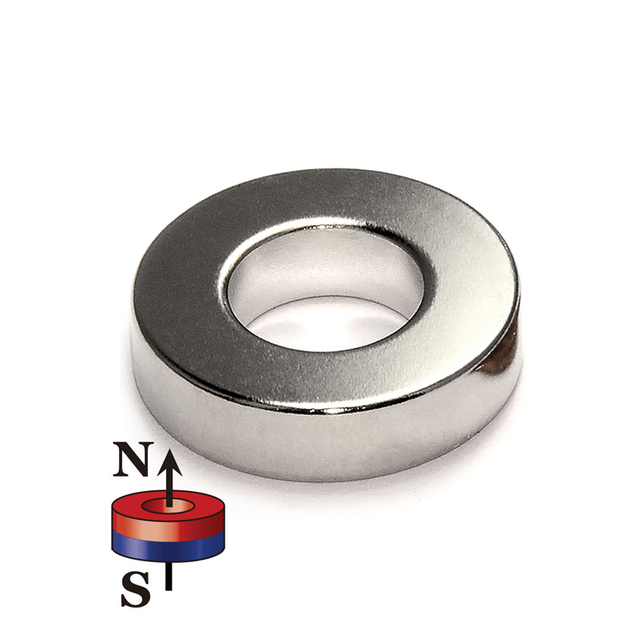

| Composite | 3 4 x 1 8 neodymium magnet | Package | customized |

| Shape | flat 3 4 x 1 8 neodymium magnet | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.About 3 4 x 1 8 neodymium magnet warranty

Neodymium magnets are generally covered by a one-year warranty against defects in materials and workmanship. The warranty does not cover damage caused by misuse, abuse, or improper handling. If a magnet is found to be defective, the manufacturer will replace it with a new one.

2.Are there any potential hazards associated with 3 4 x 1 8 neodymium magnet?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, there are potential hazards associated with neodymium magnets. They can be very powerful and can cause serious injury if swallowed. They can also pinch fingers and other body parts if two magnets are brought together too quickly. Additionally, neodymium magnets can interfere with pacemakers and other medical devices, and can damage electronic equipment if placed too close.

3.How do 3 4 x 1 8 neodymium magnet contribute to the aerospace industry?

Neodymium magnets are used in a variety of aerospace applications, including in electric motors, actuators, and sensors. They are also used in navigation systems, guidance systems, and propulsion systems. Neodymium magnets are highly resistant to corrosion and can withstand extreme temperatures, making them ideal for use in aerospace applications. Additionally, their high magnetic strength makes them ideal for use in motors and actuators, allowing for more efficient operation and greater power output.

4.What are the potential future advances in Neodymium Magnet technology?

1. Improved magnetization processes: Developing new methods to increase the magnetization of neodymium magnets, such as using high-frequency alternating current or pulsed direct current, could lead to stronger magnets. 2. Improved coating processes: Developing new methods to coat neodymium magnets with protective layers could help to reduce corrosion and improve the longevity of the magnets. 3. Improved manufacturing processes: Developing new methods to manufacture neodymium magnets more efficiently and cost-effectively could help to reduce the cost of the magnets. 4. Improved recycling processes: Developing new methods to recycle neodymium magnets could help to reduce the environmental impact of the magnets. 5. Improved magnetic field control: Developing new methods to control the magnetic field of neodymium magnets could help to improve the performance of the magnets in various applications.

5.Are 3 4 x 1 8 neodymium magnet used in headphones and speakers?

Our company has many years of 3 4 x 1 8 neodymium magnet experience and expertise. Yes, neodymium magnets are used in headphones and speakers. They are used to create a strong magnetic field that helps to produce a clear and powerful sound.

6.What is the maximum pulling force of a Neodymium Magnet?

We focus on innovation and continuous improvement to maintain a competitive advantage. The maximum pulling force of a Neodymium magnet depends on the size and shape of the magnet, but generally ranges from 10 to 200 pounds.

7.Can 3 4 x 1 8 neodymium magnet be used for magnetic therapy?

No, neodymium magnets are not recommended for use in magnetic therapy. Neodymium magnets are very powerful and can cause tissue damage if used incorrectly. It is best to consult a qualified healthcare professional before using any type of magnetic therapy.

8.About 3 4 x 1 8 neodymium magnet production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

9.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

10.Can 3 4 x 1 8 neodymium magnet be used in high-temperature environments?

Our 3 4 x 1 8 neodymium magnet products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

11.How do 3 4 x 1 8 neodymium magnet contribute to the transportation industry?

Neodymium magnets are used in a variety of transportation applications, including electric motors, generators, and brakes. They are used in electric vehicles to help reduce the weight of the vehicle and improve its efficiency. They are also used in hybrid and electric vehicles to help reduce the amount of energy needed to power the vehicle. Additionally, neodymium magnets are used in magnetic levitation trains, which use magnetic fields to lift and propel the train.

12.About 3 4 x 1 8 neodymium magnet origin

Neodymium magnets, also known as rare earth magnets, are the strongest type of permanent magnet available. They were first developed in the 1980s by General Motors and Sumitomo Special Metals. Neodymium magnets are composed of an alloy of neodymium, iron, and boron, and are used in a wide variety of applications, including motors, generators, hard drives, and speakers.

13.Can 3 4 x 1 8 neodymium magnet be used in underwater applications?

Our mission is to provide customers with the best solutions for 3 4 x 1 8 neodymium magnet. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

14.What is the magnetic field strength of a Neodymium Magnet?

The magnetic field strength of a Neodymium magnet can range from 10,000 to 14,000 gauss.

15.How do 3 4 x 1 8 neodymium magnet contribute to renewable energy sources?

Neodymium magnets are used in many renewable energy sources, such as wind turbines and solar panels. They are used to generate electricity from the rotation of the turbine blades or the movement of the sun’s rays. Neodymium magnets are also used in electric motors, which are used to power electric vehicles. Additionally, they are used in generators to convert mechanical energy into electrical energy.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.