| Availability: | |

|---|---|

| Quantity: | |

| Product Name | 3mm dia x 6mm neodymium magnets |

| Material | Neodymium Magnet/Permanet Magnet |

| Size | Various kinds or according to customers' request |

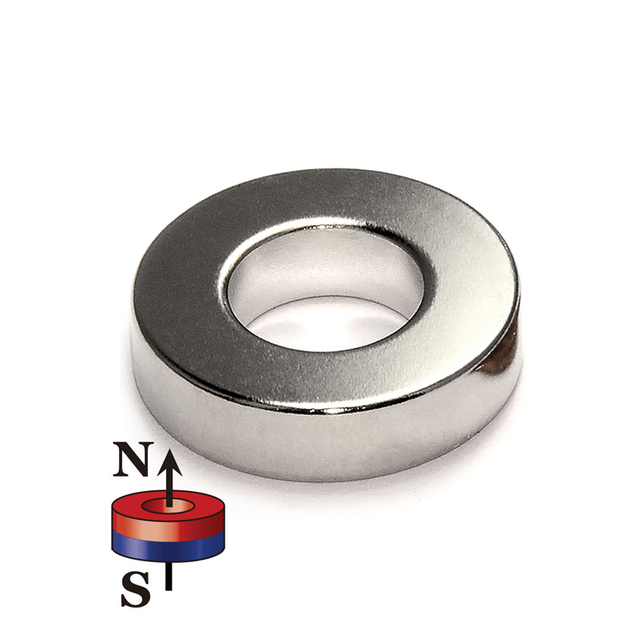

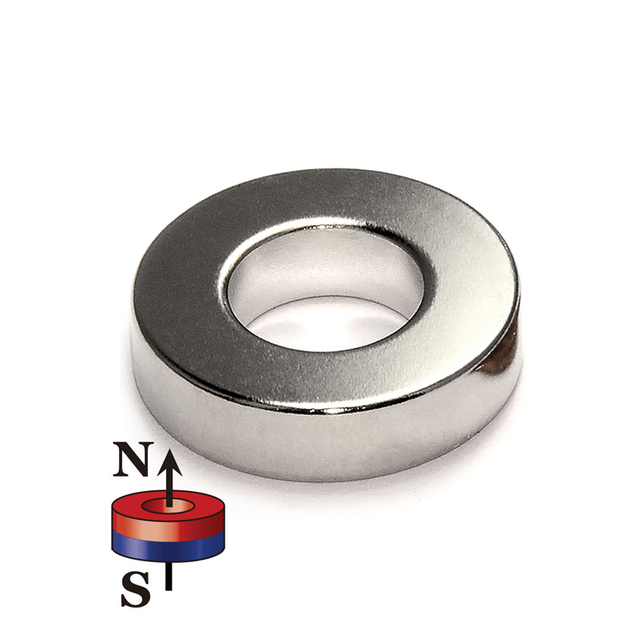

| Shape | Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Or Customized Shapes |

| Grade | N35-N52, N35M-N50M, N33H-N48H, N30SH-N35SH and so on |

| Tolerance in size | +/-0.05 mm |

| Direction of magnetisation | Through the thickness or through the diameter |

| Applications | 1. Electronic areas: speakers, headphones, acoustics, sensors and so on. 2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on. 3. Clean Tech Energy: Water flow enhancement, wind turbines. 4. Health care: MRI, medical treatment equipment. 5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on |

1.Can 3mm dia x 6mm neodymium magnets lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

2.Are 3mm dia x 6mm neodymium magnets affected by external magnetic fields?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, neodymium magnets can be affected by external magnetic fields. They can be attracted to or repelled by other magnets, and their magnetic fields can be weakened or strengthened by other magnetic fields.

3.About 3mm dia x 6mm neodymium magnets quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

4.How do 3mm dia x 6mm neodymium magnets affect electronic devices?

Being one of the top 3mm dia x 6mm neodymium magnets manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

5.About 3mm dia x 6mm neodymium magnets production equipment

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, including motors, generators, and loudspeakers. The production of neodymium magnets requires specialized equipment, such as a vacuum furnace, a press, and a sintering furnace. The process begins with the mixing of the neodymium, iron, and boron powders in the correct proportions. The mixture is then placed in a vacuum furnace and heated to a high temperature. This causes the powders to melt and form a homogenous alloy. The alloy is then placed in a press and formed into the desired shape. Finally, the formed alloy is placed in a sintering furnace and heated to a high temperature, which causes the alloy to become a permanent magnet.

6.About 3mm dia x 6mm neodymium magnets MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

7.How are 3mm dia x 6mm neodymium magnets used in motors and generators?

Our products & services cover a wide range of areas and meet the needs of different fields. Neodymium magnets are used in motors and generators to create a strong magnetic field. This magnetic field is used to create a force that can be used to turn a rotor or generate electricity. Neodymium magnets are also used in electric motors to create a strong magnetic field that can be used to turn a rotor. In generators, the magnets are used to create a strong magnetic field that can be used to generate electricity.

8.How are 3mm dia x 6mm neodymium magnets used in medicine?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Neodymium magnets are used in medicine for a variety of purposes. They are used in Magnetic Resonance Imaging (MRI) machines to create a strong magnetic field that can be used to create detailed images of the body. They are also used in Magnetic Resonance Angiography (MRA) to create images of blood vessels. Neodymium magnets are also used in Magnetic Particle Imaging (MPI) to detect and image magnetic particles in the body. Finally, they are used in Magnetic Hyperthermia Therapy (MHT) to heat up cancerous cells and destroy them.

9.Are 3mm dia x 6mm neodymium magnets expensive?

Our company has many years of 3mm dia x 6mm neodymium magnets experience and expertise. Neodymium magnets are not particularly expensive, but they can be more expensive than other types of magnets. The cost of neodymium magnets depends on the size, shape, and grade of the magnet.

10.About 3mm dia x 6mm neodymium magnets R&D capabilities

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a wide range of applications, from consumer electronics to industrial machinery. Neodymium magnets are highly resistant to demagnetization and have a high coercivity, making them ideal for applications that require a strong magnetic field. Neodymium magnets are typically produced through a process of powder metallurgy, which involves mixing the alloy components together and then pressing them into a mold. The resulting magnets are then heat-treated to increase their coercivity and strength. Research and development of neodymium magnets is ongoing, with new alloys and manufacturing processes being developed to improve the performance of these magnets. Research is also being conducted into new applications for neodymium magnets, such as in medical imaging and renewable energy technologies.

11.About the development history of 3mm dia x 6mm neodymium magnets factory

Neodymium magnets were first developed in the early 1980s by General Motors and Sumitomo Special Metals. The magnets were made from an alloy of neodymium, iron, and boron. This alloy was found to be much stronger than traditional ferrite magnets, and could be used to create much smaller and more powerful magnets. Since then, neodymium magnets have become increasingly popular and are now used in a wide variety of applications, from consumer electronics to industrial machinery. The development of neodymium magnets has also led to the development of specialized factories that produce these magnets. These factories use a variety of processes to create the magnets, including sintering, hot pressing, and injection molding. The magnets are then tested for quality and strength before being shipped to customers.

12.Can 3mm dia x 6mm neodymium magnets be used in high-temperature environments?

Our 3mm dia x 6mm neodymium magnets products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

13.About 3mm dia x 6mm neodymium magnets production management system

Neodymium magnets production management system is a software solution designed to help manufacturers of neodymium magnets manage their production processes. The system provides a comprehensive set of tools to help streamline production, from tracking orders and inventory to managing quality control and production scheduling. It also provides detailed reporting and analytics to help manufacturers make informed decisions about their production processes. The system is designed to be user-friendly and intuitive, allowing users to quickly and easily access the information they need.

14.What are the pros and cons of using 3mm dia x 6mm neodymium magnets?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Pros: - Neodymium magnets are extremely strong and can hold a large amount of weight. - They are very versatile and can be used in a variety of applications. - They are relatively inexpensive and easy to find. - They are corrosion-resistant and can withstand extreme temperatures. Cons: - Neodymium magnets are brittle and can easily break if dropped or mishandled. - They can be dangerous if swallowed, as they can cause serious internal damage. - They can be difficult to work with due to their strength. - They can be expensive depending on the size and grade of the magnet.

| Product Name | 3mm dia x 6mm neodymium magnets |

| Material | Neodymium Magnet/Permanet Magnet |

| Size | Various kinds or according to customers' request |

| Shape | Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Or Customized Shapes |

| Grade | N35-N52, N35M-N50M, N33H-N48H, N30SH-N35SH and so on |

| Tolerance in size | +/-0.05 mm |

| Direction of magnetisation | Through the thickness or through the diameter |

| Applications | 1. Electronic areas: speakers, headphones, acoustics, sensors and so on. 2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on. 3. Clean Tech Energy: Water flow enhancement, wind turbines. 4. Health care: MRI, medical treatment equipment. 5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on |

1.Can 3mm dia x 6mm neodymium magnets lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

2.Are 3mm dia x 6mm neodymium magnets affected by external magnetic fields?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, neodymium magnets can be affected by external magnetic fields. They can be attracted to or repelled by other magnets, and their magnetic fields can be weakened or strengthened by other magnetic fields.

3.About 3mm dia x 6mm neodymium magnets quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

4.How do 3mm dia x 6mm neodymium magnets affect electronic devices?

Being one of the top 3mm dia x 6mm neodymium magnets manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

5.About 3mm dia x 6mm neodymium magnets production equipment

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, including motors, generators, and loudspeakers. The production of neodymium magnets requires specialized equipment, such as a vacuum furnace, a press, and a sintering furnace. The process begins with the mixing of the neodymium, iron, and boron powders in the correct proportions. The mixture is then placed in a vacuum furnace and heated to a high temperature. This causes the powders to melt and form a homogenous alloy. The alloy is then placed in a press and formed into the desired shape. Finally, the formed alloy is placed in a sintering furnace and heated to a high temperature, which causes the alloy to become a permanent magnet.

6.About 3mm dia x 6mm neodymium magnets MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

7.How are 3mm dia x 6mm neodymium magnets used in motors and generators?

Our products & services cover a wide range of areas and meet the needs of different fields. Neodymium magnets are used in motors and generators to create a strong magnetic field. This magnetic field is used to create a force that can be used to turn a rotor or generate electricity. Neodymium magnets are also used in electric motors to create a strong magnetic field that can be used to turn a rotor. In generators, the magnets are used to create a strong magnetic field that can be used to generate electricity.

8.How are 3mm dia x 6mm neodymium magnets used in medicine?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Neodymium magnets are used in medicine for a variety of purposes. They are used in Magnetic Resonance Imaging (MRI) machines to create a strong magnetic field that can be used to create detailed images of the body. They are also used in Magnetic Resonance Angiography (MRA) to create images of blood vessels. Neodymium magnets are also used in Magnetic Particle Imaging (MPI) to detect and image magnetic particles in the body. Finally, they are used in Magnetic Hyperthermia Therapy (MHT) to heat up cancerous cells and destroy them.

9.Are 3mm dia x 6mm neodymium magnets expensive?

Our company has many years of 3mm dia x 6mm neodymium magnets experience and expertise. Neodymium magnets are not particularly expensive, but they can be more expensive than other types of magnets. The cost of neodymium magnets depends on the size, shape, and grade of the magnet.

10.About 3mm dia x 6mm neodymium magnets R&D capabilities

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a wide range of applications, from consumer electronics to industrial machinery. Neodymium magnets are highly resistant to demagnetization and have a high coercivity, making them ideal for applications that require a strong magnetic field. Neodymium magnets are typically produced through a process of powder metallurgy, which involves mixing the alloy components together and then pressing them into a mold. The resulting magnets are then heat-treated to increase their coercivity and strength. Research and development of neodymium magnets is ongoing, with new alloys and manufacturing processes being developed to improve the performance of these magnets. Research is also being conducted into new applications for neodymium magnets, such as in medical imaging and renewable energy technologies.

11.About the development history of 3mm dia x 6mm neodymium magnets factory

Neodymium magnets were first developed in the early 1980s by General Motors and Sumitomo Special Metals. The magnets were made from an alloy of neodymium, iron, and boron. This alloy was found to be much stronger than traditional ferrite magnets, and could be used to create much smaller and more powerful magnets. Since then, neodymium magnets have become increasingly popular and are now used in a wide variety of applications, from consumer electronics to industrial machinery. The development of neodymium magnets has also led to the development of specialized factories that produce these magnets. These factories use a variety of processes to create the magnets, including sintering, hot pressing, and injection molding. The magnets are then tested for quality and strength before being shipped to customers.

12.Can 3mm dia x 6mm neodymium magnets be used in high-temperature environments?

Our 3mm dia x 6mm neodymium magnets products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

13.About 3mm dia x 6mm neodymium magnets production management system

Neodymium magnets production management system is a software solution designed to help manufacturers of neodymium magnets manage their production processes. The system provides a comprehensive set of tools to help streamline production, from tracking orders and inventory to managing quality control and production scheduling. It also provides detailed reporting and analytics to help manufacturers make informed decisions about their production processes. The system is designed to be user-friendly and intuitive, allowing users to quickly and easily access the information they need.

14.What are the pros and cons of using 3mm dia x 6mm neodymium magnets?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. Pros: - Neodymium magnets are extremely strong and can hold a large amount of weight. - They are very versatile and can be used in a variety of applications. - They are relatively inexpensive and easy to find. - They are corrosion-resistant and can withstand extreme temperatures. Cons: - Neodymium magnets are brittle and can easily break if dropped or mishandled. - They can be dangerous if swallowed, as they can cause serious internal damage. - They can be difficult to work with due to their strength. - They can be expensive depending on the size and grade of the magnet.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.