| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~71℃ |

| Type | Permanent | Delivery time | 3-15days |

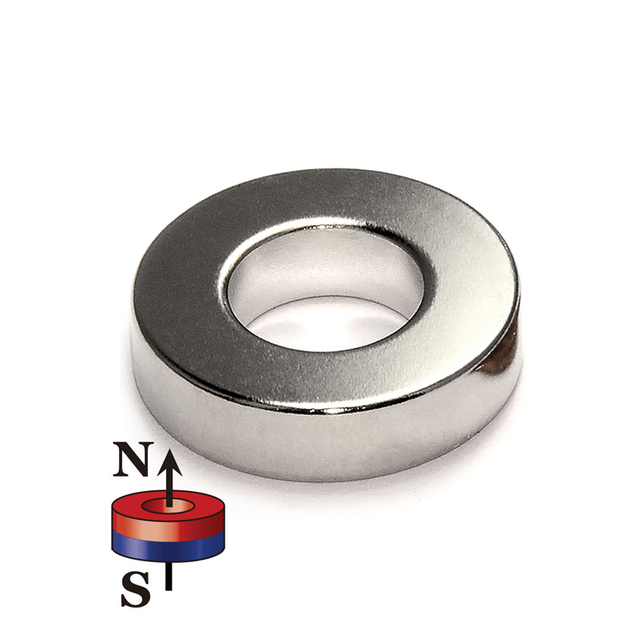

| Composite | 6.5 bass subwoofer neodymium magnetic | Package | customized |

| Shape | sticky 6.5 bass subwoofer neodymium magnetic | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.Are 6.5 bass subwoofer neodymium magnetic affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

2.How do you prevent 6.5 bass subwoofer neodymium magnetic from corroding?

We continuously upgrade our skills and knowledge to adapt to changing 6.5 bass subwoofer neodymium magnetic market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

3.About 6.5 bass subwoofer neodymium magnetic production equipment

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, including motors, generators, and loudspeakers. The production of neodymium magnets requires specialized equipment, such as a vacuum furnace, a press, and a sintering furnace. The process begins with the mixing of the neodymium, iron, and boron powders in the correct proportions. The mixture is then placed in a vacuum furnace and heated to a high temperature. This causes the powders to melt and form a homogenous alloy. The alloy is then placed in a press and formed into the desired shape. Finally, the formed alloy is placed in a sintering furnace and heated to a high temperature, which causes the alloy to become a permanent magnet.

4.What makes 6.5 bass subwoofer neodymium magnetic different from other types of magnets?

We are a professional 6.5 bass subwoofer neodymium magnetic company dedicated to providing high quality products and services. Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron and are much stronger than other types of magnets, such as ceramic or alnico magnets. Neodymium magnets are also more resistant to demagnetization than other types of magnets, making them ideal for applications where a strong, permanent magnet is needed.

5.About 6.5 bass subwoofer neodymium magnetic inventory

Neodymium magnets are a type of rare earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a wide variety of applications, from industrial to consumer products. Neodymium magnets are available in a variety of shapes and sizes, and can be purchased in bulk or as individual pieces.

6.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

7.How do 6.5 bass subwoofer neodymium magnetic compare to Samarium Cobalt Magnets?

6.5 bass subwoofer neodymium magnetic is not a product only, but also can help you comes to money-making. Neodymium magnets are the strongest type of permanent magnet available, and they are much stronger than samarium cobalt magnets. Neodymium magnets are also much more affordable than samarium cobalt magnets, making them the more popular choice for many applications. Neodymium magnets are also more resistant to corrosion and temperature changes than samarium cobalt magnets.

8.What are the properties of 6.5 bass subwoofer neodymium magnetic?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Neodymium magnets are the strongest type of permanent magnet available. 2. They are composed of an alloy of neodymium, iron, and boron. 3. They have a high resistance to demagnetization. 4. They have a high coercivity, meaning they can maintain their magnetic properties even in the presence of other magnetic fields. 5. They have a high energy density, meaning they can generate a strong magnetic field in a small volume. 6. They are brittle and prone to cracking or shattering if dropped or handled improperly. 7. They are susceptible to corrosion if not properly coated.

9.Can 6.5 bass subwoofer neodymium magnetic be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

10.About 6.5 bass subwoofer neodymium magnetic production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

11.About 6.5 bass subwoofer neodymium magnetic production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

12.How do you demagnetize a Neodymium Magnet?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Neodymium magnets can be demagnetized by heating them to a temperature of around 200°C (392°F) for a few minutes. This will cause the magnet to lose its magnetic properties. It is also possible to demagnetize a neodymium magnet by exposing it to a strong alternating magnetic field.

13.Why are 6.5 bass subwoofer neodymium magnetic considered to be the strongest permanent magnets?

As one of the top 6.5 bass subwoofer neodymium magnetic manufacturers in China, we take this very seriously. Neodymium magnets are considered to be the strongest permanent magnets because they are made from an alloy of neodymium, iron, and boron. This alloy creates a strong magnetic field due to the way the atoms are arranged. The magnetic field created by neodymium magnets is much stronger than that of other permanent magnets, such as ferrite or alnico.

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~71℃ |

| Type | Permanent | Delivery time | 3-15days |

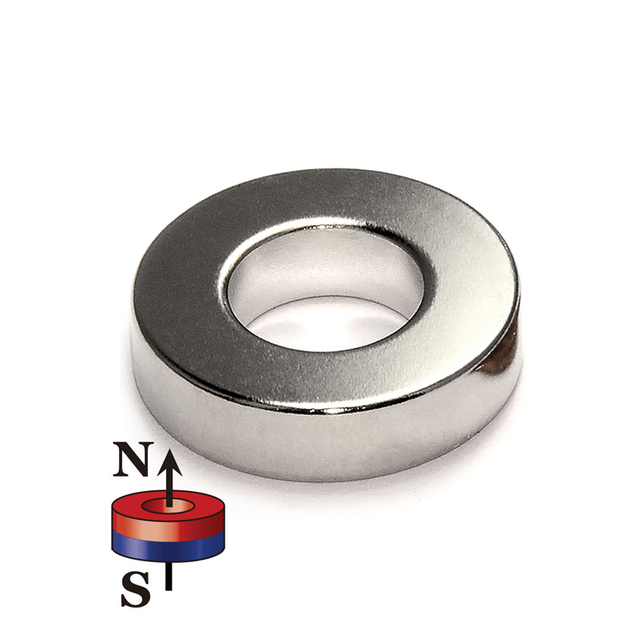

| Composite | 6.5 bass subwoofer neodymium magnetic | Package | customized |

| Shape | sticky 6.5 bass subwoofer neodymium magnetic | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.Are 6.5 bass subwoofer neodymium magnetic affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

2.How do you prevent 6.5 bass subwoofer neodymium magnetic from corroding?

We continuously upgrade our skills and knowledge to adapt to changing 6.5 bass subwoofer neodymium magnetic market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

3.About 6.5 bass subwoofer neodymium magnetic production equipment

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, including motors, generators, and loudspeakers. The production of neodymium magnets requires specialized equipment, such as a vacuum furnace, a press, and a sintering furnace. The process begins with the mixing of the neodymium, iron, and boron powders in the correct proportions. The mixture is then placed in a vacuum furnace and heated to a high temperature. This causes the powders to melt and form a homogenous alloy. The alloy is then placed in a press and formed into the desired shape. Finally, the formed alloy is placed in a sintering furnace and heated to a high temperature, which causes the alloy to become a permanent magnet.

4.What makes 6.5 bass subwoofer neodymium magnetic different from other types of magnets?

We are a professional 6.5 bass subwoofer neodymium magnetic company dedicated to providing high quality products and services. Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron and are much stronger than other types of magnets, such as ceramic or alnico magnets. Neodymium magnets are also more resistant to demagnetization than other types of magnets, making them ideal for applications where a strong, permanent magnet is needed.

5.About 6.5 bass subwoofer neodymium magnetic inventory

Neodymium magnets are a type of rare earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a wide variety of applications, from industrial to consumer products. Neodymium magnets are available in a variety of shapes and sizes, and can be purchased in bulk or as individual pieces.

6.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

7.How do 6.5 bass subwoofer neodymium magnetic compare to Samarium Cobalt Magnets?

6.5 bass subwoofer neodymium magnetic is not a product only, but also can help you comes to money-making. Neodymium magnets are the strongest type of permanent magnet available, and they are much stronger than samarium cobalt magnets. Neodymium magnets are also much more affordable than samarium cobalt magnets, making them the more popular choice for many applications. Neodymium magnets are also more resistant to corrosion and temperature changes than samarium cobalt magnets.

8.What are the properties of 6.5 bass subwoofer neodymium magnetic?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Neodymium magnets are the strongest type of permanent magnet available. 2. They are composed of an alloy of neodymium, iron, and boron. 3. They have a high resistance to demagnetization. 4. They have a high coercivity, meaning they can maintain their magnetic properties even in the presence of other magnetic fields. 5. They have a high energy density, meaning they can generate a strong magnetic field in a small volume. 6. They are brittle and prone to cracking or shattering if dropped or handled improperly. 7. They are susceptible to corrosion if not properly coated.

9.Can 6.5 bass subwoofer neodymium magnetic be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

10.About 6.5 bass subwoofer neodymium magnetic production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

11.About 6.5 bass subwoofer neodymium magnetic production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

12.How do you demagnetize a Neodymium Magnet?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Neodymium magnets can be demagnetized by heating them to a temperature of around 200°C (392°F) for a few minutes. This will cause the magnet to lose its magnetic properties. It is also possible to demagnetize a neodymium magnet by exposing it to a strong alternating magnetic field.

13.Why are 6.5 bass subwoofer neodymium magnetic considered to be the strongest permanent magnets?

As one of the top 6.5 bass subwoofer neodymium magnetic manufacturers in China, we take this very seriously. Neodymium magnets are considered to be the strongest permanent magnets because they are made from an alloy of neodymium, iron, and boron. This alloy creates a strong magnetic field due to the way the atoms are arranged. The magnetic field created by neodymium magnets is much stronger than that of other permanent magnets, such as ferrite or alnico.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.