| Availability: | |

|---|---|

| Quantity: | |

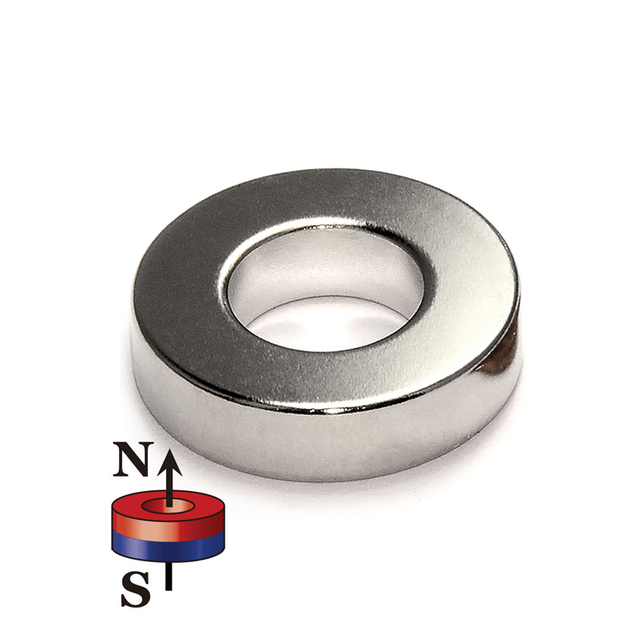

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~98℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | neodymium iron boron magnets | Package | customized |

| Shape | magnetic disk neodymium iron boron magnets | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.About neodymium iron boron magnets MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

2.What types of coatings are used on neodymium iron boron magnets?

Our mission is to provide customers with the best solutions for neodymium iron boron magnets. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

3.Are neodymium iron boron magnets affected by external magnetic fields?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, neodymium magnets can be affected by external magnetic fields. They can be attracted to or repelled by other magnets, and their magnetic fields can be weakened or strengthened by other magnetic fields.

4.Why are neodymium iron boron magnets coated?

We have established a good reputation and reliable partnerships within the neodymium iron boron magnets industry. Neodymium magnets are coated to protect them from corrosion and to prevent them from chipping or cracking. The coating also helps to reduce the risk of the magnet being damaged by other metals or objects.

5.How do neodymium iron boron magnets compare to traditional ceramic magnets?

Neodymium magnets are much stronger than traditional ceramic magnets. They are made from an alloy of neodymium, iron, and boron and are the strongest type of permanent magnet available. Neodymium magnets are much smaller than ceramic magnets and can generate significantly higher magnetic fields. They are also more expensive than ceramic magnets.

6.About neodymium iron boron magnets patent

Neodymium magnets are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications, including motors, generators, and loudspeakers. Neodymium magnets are protected by a number of patents, including US Patent No. 6,845,845, which covers the composition and manufacturing process of the magnets.

7.About the scale of neodymium iron boron magnets factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

8.How are neodymium iron boron magnets used in magnetic resonance imaging (MRI)?

Neodymium magnets are used in MRI machines to create a strong magnetic field that is used to align the hydrogen atoms in the body. This alignment allows the MRI machine to detect the signals from the hydrogen atoms and create detailed images of the body. The strong magnetic field also helps to reduce the amount of time it takes to acquire the images.

9.What role do neodymium iron boron magnets play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

10.Can neodymium iron boron magnets be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

11.Can neodymium iron boron magnets be used for magnetic therapy?

No, neodymium magnets are not recommended for use in magnetic therapy. Neodymium magnets are very powerful and can cause tissue damage if used incorrectly. It is best to consult a qualified healthcare professional before using any type of magnetic therapy.

12.What is the maximum operating temperature of neodymium iron boron magnets?

We continuously upgrade our skills and knowledge to adapt to changing neodymium iron boron magnets market needs. The maximum operating temperature of Neodymium Magnets is 80°C (176°F).

13.Are there any restrictions on the production or use of neodymium iron boron magnets?

Yes, there are restrictions on the production and use of neodymium magnets. Neodymium magnets are subject to the European Union's Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electrical and electronic equipment. Additionally, neodymium magnets are subject to the International Maritime Organization's (IMO) International Maritime Dangerous Goods (IMDG) Code, which regulates the transport of hazardous materials by sea. Finally, neodymium magnets are subject to the United Nations' International Atomic Energy Agency (IAEA) regulations, which regulate the use of radioactive materials.

14.What is the weight-to-strength ratio of neodymium iron boron magnets?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

15.About neodymium iron boron magnets production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

16.About neodymium iron boron magnets production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

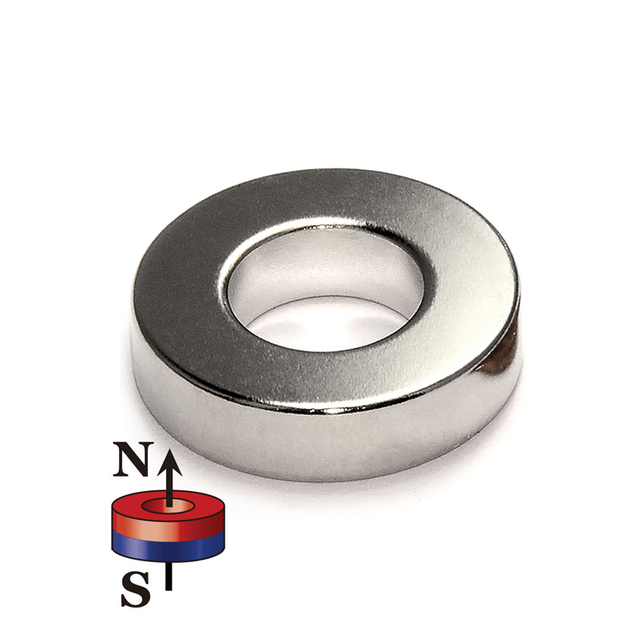

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~98℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | neodymium iron boron magnets | Package | customized |

| Shape | magnetic disk neodymium iron boron magnets | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.About neodymium iron boron magnets MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

2.What types of coatings are used on neodymium iron boron magnets?

Our mission is to provide customers with the best solutions for neodymium iron boron magnets. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

3.Are neodymium iron boron magnets affected by external magnetic fields?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, neodymium magnets can be affected by external magnetic fields. They can be attracted to or repelled by other magnets, and their magnetic fields can be weakened or strengthened by other magnetic fields.

4.Why are neodymium iron boron magnets coated?

We have established a good reputation and reliable partnerships within the neodymium iron boron magnets industry. Neodymium magnets are coated to protect them from corrosion and to prevent them from chipping or cracking. The coating also helps to reduce the risk of the magnet being damaged by other metals or objects.

5.How do neodymium iron boron magnets compare to traditional ceramic magnets?

Neodymium magnets are much stronger than traditional ceramic magnets. They are made from an alloy of neodymium, iron, and boron and are the strongest type of permanent magnet available. Neodymium magnets are much smaller than ceramic magnets and can generate significantly higher magnetic fields. They are also more expensive than ceramic magnets.

6.About neodymium iron boron magnets patent

Neodymium magnets are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications, including motors, generators, and loudspeakers. Neodymium magnets are protected by a number of patents, including US Patent No. 6,845,845, which covers the composition and manufacturing process of the magnets.

7.About the scale of neodymium iron boron magnets factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

8.How are neodymium iron boron magnets used in magnetic resonance imaging (MRI)?

Neodymium magnets are used in MRI machines to create a strong magnetic field that is used to align the hydrogen atoms in the body. This alignment allows the MRI machine to detect the signals from the hydrogen atoms and create detailed images of the body. The strong magnetic field also helps to reduce the amount of time it takes to acquire the images.

9.What role do neodymium iron boron magnets play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

10.Can neodymium iron boron magnets be shaped to fit specific applications?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. Yes, neodymium magnets can be shaped to fit specific applications. They can be cut, drilled, and machined into various shapes and sizes.

11.Can neodymium iron boron magnets be used for magnetic therapy?

No, neodymium magnets are not recommended for use in magnetic therapy. Neodymium magnets are very powerful and can cause tissue damage if used incorrectly. It is best to consult a qualified healthcare professional before using any type of magnetic therapy.

12.What is the maximum operating temperature of neodymium iron boron magnets?

We continuously upgrade our skills and knowledge to adapt to changing neodymium iron boron magnets market needs. The maximum operating temperature of Neodymium Magnets is 80°C (176°F).

13.Are there any restrictions on the production or use of neodymium iron boron magnets?

Yes, there are restrictions on the production and use of neodymium magnets. Neodymium magnets are subject to the European Union's Restriction of Hazardous Substances (RoHS) directive, which restricts the use of certain hazardous materials in electrical and electronic equipment. Additionally, neodymium magnets are subject to the International Maritime Organization's (IMO) International Maritime Dangerous Goods (IMDG) Code, which regulates the transport of hazardous materials by sea. Finally, neodymium magnets are subject to the United Nations' International Atomic Energy Agency (IAEA) regulations, which regulate the use of radioactive materials.

14.What is the weight-to-strength ratio of neodymium iron boron magnets?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

15.About neodymium iron boron magnets production skills training

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets production skills training is designed to teach participants the basics of producing neodymium magnets. The training covers topics such as the properties of neodymium magnets, the manufacturing process, and safety considerations. Participants will also learn about the different types of neodymium magnets and their uses. The training is designed to give participants the knowledge and skills needed to produce neodymium magnets in a safe and efficient manner.

16.About neodymium iron boron magnets production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.