| Availability: | |

|---|---|

| Quantity: | |

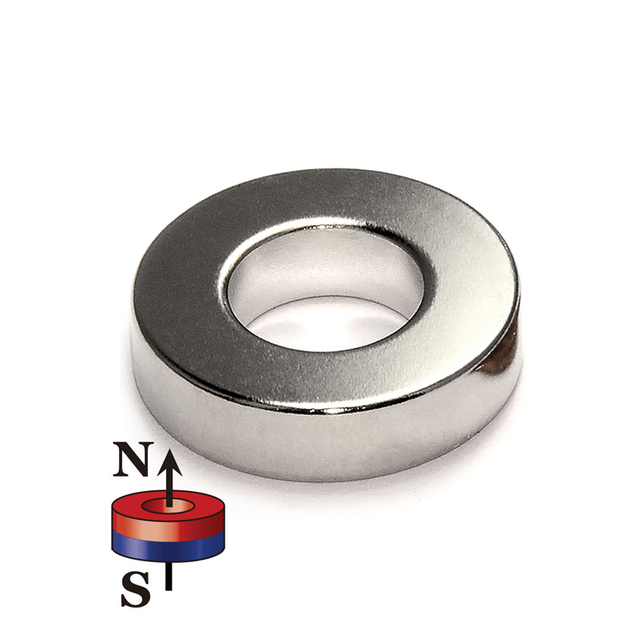

| Product Name | neodymium magneten |

| Material | Neodymium (Nd), Iron (Fe), and Boron (B) |

| Size | Customized size |

| Shape | Customized (block,Disc,Cylinder, Bar, Ring,Arc,Countersunk, Segment, hook) |

| Coating | Customised (Ni, Zn, Epoxy, Gold, etc.) |

| Size tolerance | ±0.05mm for diamater / thickness, ±0.1mm for width / length |

| Density | 5.6-9.1g/cm³ |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors,microphones, wind turbines, wind generators,printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

1.About the scale of neodymium magneten factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

2.What are the safety precautions when handling neodymium magneten?

We are a professional neodymium magneten company dedicated to providing high quality products and services. 1. Keep magnets away from children and pets. 2. Wear protective gloves and eye protection when handling magnets. 3. Do not allow magnets to snap together or impact each other. 4. Do not allow magnets to come into contact with electronic devices, such as computers, cell phones, and credit cards. 5. Do not allow magnets to come into contact with pacemakers or other medical devices. 6. Do not allow magnets to come into contact with magnetic media, such as floppy disks, credit cards, and videotapes. 7. Do not allow magnets to come into contact with each other, as they can become permanently magnetized. 8. Do not allow magnets to come into contact with flammable materials, such as gasoline, paint, and solvents. 9. Do not allow magnets to come into contact with liquids, as they can corrode. 10. Store magnets in a dry, cool place away from direct sunlight.

3.About neodymium magneten production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

4.Can neodymium magneten be custom-made for specific applications?

Yes, neodymium magnets can be custom-made for specific applications. Depending on the application, the size, shape, and strength of the magnet can be tailored to meet the specific requirements.

5.About neodymium magneten delivery date

Neodymium magnets are usually shipped within 1-2 business days of ordering. Depending on the size and quantity of the magnets, delivery times may vary.

6.Can neodymium magneten damage credit cards or electronic devices?

Being one of the top neodymium magneten manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

7.What are the limitations of using neodymium magneten?

As one of the top neodymium magneten manufacturers in China, we take this very seriously. 1. Neodymium magnets are brittle and can easily break or chip if dropped or handled roughly. 2. Neodymium magnets can corrode if exposed to moisture or other corrosive elements. 3. Neodymium magnets can be difficult to machine and require special tools and techniques. 4. Neodymium magnets can be difficult to demagnetize and require special tools and techniques. 5. Neodymium magnets can be expensive compared to other types of magnets.

8.How do you recycle neodymium magneten?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

9.What types of coatings are used on neodymium magneten?

Our mission is to provide customers with the best solutions for neodymium magneten. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

10.Are there any health risks associated with neodymium magneten?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, there are some health risks associated with neodymium magnets. If swallowed, they can cause serious injury or even death. They can also pinch skin and cause cuts or bruises if handled improperly. Additionally, they can interfere with pacemakers and other medical devices.

11.Are neodymium magneten safe to handle?

neodymium magneten is not a product only, but also can help you comes to money-making. Yes, neodymium magnets are safe to handle as long as they are handled with care. Neodymium magnets are very strong and can cause injury if not handled properly. It is important to keep them away from children and pets, and to avoid contact with other magnets or metal objects.

12.Are neodymium magneten affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

13.About neodymium magneten quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

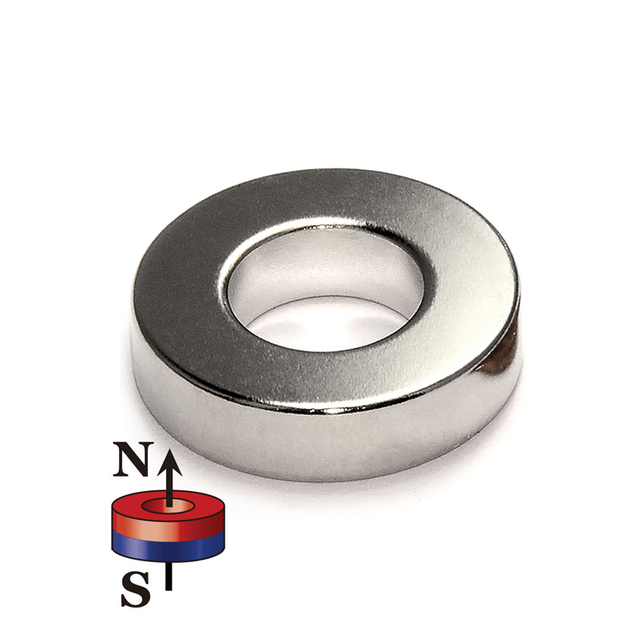

| Product Name | neodymium magneten |

| Material | Neodymium (Nd), Iron (Fe), and Boron (B) |

| Size | Customized size |

| Shape | Customized (block,Disc,Cylinder, Bar, Ring,Arc,Countersunk, Segment, hook) |

| Coating | Customised (Ni, Zn, Epoxy, Gold, etc.) |

| Size tolerance | ±0.05mm for diamater / thickness, ±0.1mm for width / length |

| Density | 5.6-9.1g/cm³ |

| Magnetization | Thickness Magnetized, Axially Magnetized, Diametrally Magnetized |

| Applications | Neodymium(NdFeB) Magnet are widely used in many fields, such as motors, sensors,microphones, wind turbines, wind generators,printer, switchboard, packing box , loudspeakers, magnetic separation, magnetic hooks, magnetic holder, magnetic chuck, ect. |

1.About the scale of neodymium magneten factory

Neodymium magnets are produced in a variety of sizes, shapes, and grades. The size of a neodymium magnet factory can vary greatly depending on the type of magnets being produced. Some factories may only produce small magnets, while others may produce large magnets for industrial applications. The size of the factory also depends on the number of employees and the amount of equipment needed to produce the magnets.

2.What are the safety precautions when handling neodymium magneten?

We are a professional neodymium magneten company dedicated to providing high quality products and services. 1. Keep magnets away from children and pets. 2. Wear protective gloves and eye protection when handling magnets. 3. Do not allow magnets to snap together or impact each other. 4. Do not allow magnets to come into contact with electronic devices, such as computers, cell phones, and credit cards. 5. Do not allow magnets to come into contact with pacemakers or other medical devices. 6. Do not allow magnets to come into contact with magnetic media, such as floppy disks, credit cards, and videotapes. 7. Do not allow magnets to come into contact with each other, as they can become permanently magnetized. 8. Do not allow magnets to come into contact with flammable materials, such as gasoline, paint, and solvents. 9. Do not allow magnets to come into contact with liquids, as they can corrode. 10. Store magnets in a dry, cool place away from direct sunlight.

3.About neodymium magneten production capacity

Neodymium magnets are the strongest type of permanent magnet available. They are made from an alloy of neodymium, iron, and boron. The global production capacity of neodymium magnets is estimated to be around 10,000 tons per year. The majority of neodymium magnets are produced in China, with other countries such as Japan, the United States, and Germany also producing them.

4.Can neodymium magneten be custom-made for specific applications?

Yes, neodymium magnets can be custom-made for specific applications. Depending on the application, the size, shape, and strength of the magnet can be tailored to meet the specific requirements.

5.About neodymium magneten delivery date

Neodymium magnets are usually shipped within 1-2 business days of ordering. Depending on the size and quantity of the magnets, delivery times may vary.

6.Can neodymium magneten damage credit cards or electronic devices?

Being one of the top neodymium magneten manufacturers in China, We attach great importance to this detail. No, neodymium magnets will not damage credit cards or electronic devices. However, it is important to keep in mind that neodymium magnets are very powerful and can cause damage to other magnetic materials, such as hard drives, speakers, and other electronic components. Therefore, it is important to keep neodymium magnets away from any electronic devices.

7.What are the limitations of using neodymium magneten?

As one of the top neodymium magneten manufacturers in China, we take this very seriously. 1. Neodymium magnets are brittle and can easily break or chip if dropped or handled roughly. 2. Neodymium magnets can corrode if exposed to moisture or other corrosive elements. 3. Neodymium magnets can be difficult to machine and require special tools and techniques. 4. Neodymium magnets can be difficult to demagnetize and require special tools and techniques. 5. Neodymium magnets can be expensive compared to other types of magnets.

8.How do you recycle neodymium magneten?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

9.What types of coatings are used on neodymium magneten?

Our mission is to provide customers with the best solutions for neodymium magneten. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

10.Are there any health risks associated with neodymium magneten?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Yes, there are some health risks associated with neodymium magnets. If swallowed, they can cause serious injury or even death. They can also pinch skin and cause cuts or bruises if handled improperly. Additionally, they can interfere with pacemakers and other medical devices.

11.Are neodymium magneten safe to handle?

neodymium magneten is not a product only, but also can help you comes to money-making. Yes, neodymium magnets are safe to handle as long as they are handled with care. Neodymium magnets are very strong and can cause injury if not handled properly. It is important to keep them away from children and pets, and to avoid contact with other magnets or metal objects.

12.Are neodymium magneten affected by extreme temperatures?

Yes, neodymium magnets can be affected by extreme temperatures. They can become brittle and crack if exposed to temperatures above 175°C (347°F). They can also lose their magnetism if exposed to temperatures below -45°C (-49°F).

13.About neodymium magneten quality system

Neodymium magnets are a type of rare earth magnet that is composed of an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications. The quality of neodymium magnets is determined by the purity of the raw materials used in their manufacture, the manufacturing process, and the quality control measures in place. Quality control measures include testing for magnetic strength, corrosion resistance, and dimensional accuracy. Quality systems are in place to ensure that neodymium magnets meet the required specifications and are safe for use in the intended application.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.