| Availability: | |

|---|---|

| Quantity: | |

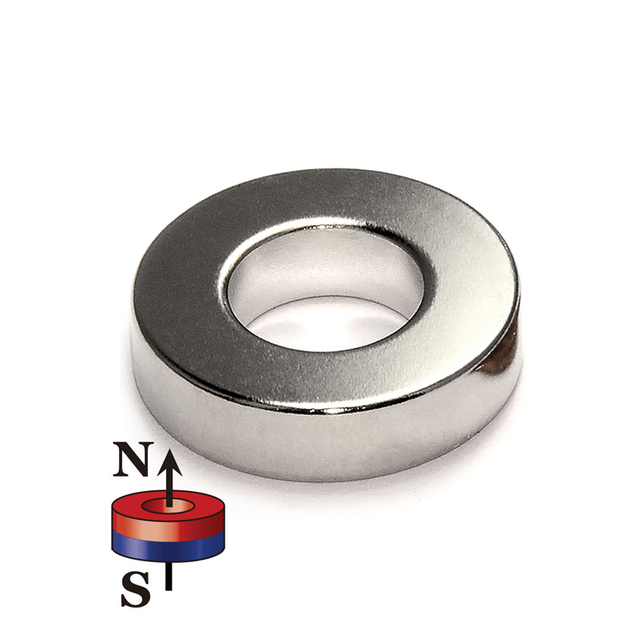

| Product Name | neodymium magnets countersunk hole |

| Material | Neodymium Magnet/Permanet Magnet |

| Size | Various kinds or according to customers' request |

| Shape | Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Or Customized Shapes |

| Grade | N35-N52, N35M-N50M, N33H-N48H, N30SH-N35SH and so on |

| Tolerance in size | +/-0.05 mm |

| Direction of magnetisation | Through the thickness or through the diameter |

| Applications | 1. Electronic areas: speakers, headphones, acoustics, sensors and so on. 2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on. 3. Clean Tech Energy: Water flow enhancement, wind turbines. 4. Health care: MRI, medical treatment equipment. 5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on |

1.Can neodymium magnets countersunk hole be used in underwater applications?

Our mission is to provide customers with the best solutions for neodymium magnets countersunk hole. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

2.How do neodymium magnets countersunk hole contribute to the transportation industry?

Neodymium magnets are used in a variety of transportation applications, including electric motors, generators, and brakes. They are used in electric vehicles to help reduce the weight of the vehicle and improve its efficiency. They are also used in hybrid and electric vehicles to help reduce the amount of energy needed to power the vehicle. Additionally, neodymium magnets are used in magnetic levitation trains, which use magnetic fields to lift and propel the train.

3.What is the weight-to-strength ratio of neodymium magnets countersunk hole?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

4.How are neodymium magnets countersunk hole used in magnetic resonance imaging (MRI)?

Neodymium magnets are used in MRI machines to create a strong magnetic field that is used to align the hydrogen atoms in the body. This alignment allows the MRI machine to detect the signals from the hydrogen atoms and create detailed images of the body. The strong magnetic field also helps to reduce the amount of time it takes to acquire the images.

5.Can neodymium magnets countersunk hole be used in high-temperature environments?

Our neodymium magnets countersunk hole products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

6.What types of coatings are used on neodymium magnets countersunk hole?

Our mission is to provide customers with the best solutions for neodymium magnets countersunk hole. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

7.How do you prevent neodymium magnets countersunk hole from corroding?

We continuously upgrade our skills and knowledge to adapt to changing neodymium magnets countersunk hole market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

8.About neodymium magnets countersunk hole customization services

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets can be customized to meet specific requirements, such as size, shape, and strength. Customization services can include machining, coating, and assembly. Customized neodymium magnets can be used in a variety of applications, including motors, sensors, and medical devices.

9.Are neodymium magnets countersunk hole used in electric vehicles?

Yes, neodymium magnets are used in electric vehicles. They are used in the electric motors that power the vehicle, as well as in the batteries that store the energy. Neodymium magnets are also used in the regenerative braking systems of electric vehicles, which help to capture and store energy that would otherwise be lost as heat.

10.Are there any ethical concerns regarding the use of neodymium magnets countersunk hole?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

11.How do neodymium magnets countersunk hole affect electronic devices?

Being one of the top neodymium magnets countersunk hole manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

12.What are the properties of neodymium magnets countersunk hole?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Neodymium magnets are the strongest type of permanent magnet available. 2. They are composed of an alloy of neodymium, iron, and boron. 3. They have a high resistance to demagnetization. 4. They have a high coercivity, meaning they can maintain their magnetic properties even in the presence of other magnetic fields. 5. They have a high energy density, meaning they can generate a strong magnetic field in a small volume. 6. They are brittle and prone to cracking or shattering if dropped or handled improperly. 7. They are susceptible to corrosion if not properly coated.

13.What advancements are being made in the recycling of neodymium magnets countersunk hole?

Recent advancements in the recycling of neodymium magnets include the development of new technologies that allow for the separation of neodymium from other metals in the magnet, such as iron and cobalt. This allows for the recovery of the neodymium for reuse in new magnets. Additionally, new methods of recycling neodymium magnets have been developed that involve crushing the magnets into a powder and then separating the neodymium from the other metals. This powder can then be used to create new magnets.

14.About neodymium magnets countersunk hole MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

15.How do you recycle neodymium magnets countersunk hole?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

16.What is the maximum operating temperature of neodymium magnets countersunk hole?

We continuously upgrade our skills and knowledge to adapt to changing neodymium magnets countersunk hole market needs. The maximum operating temperature of Neodymium Magnets is 80°C (176°F).

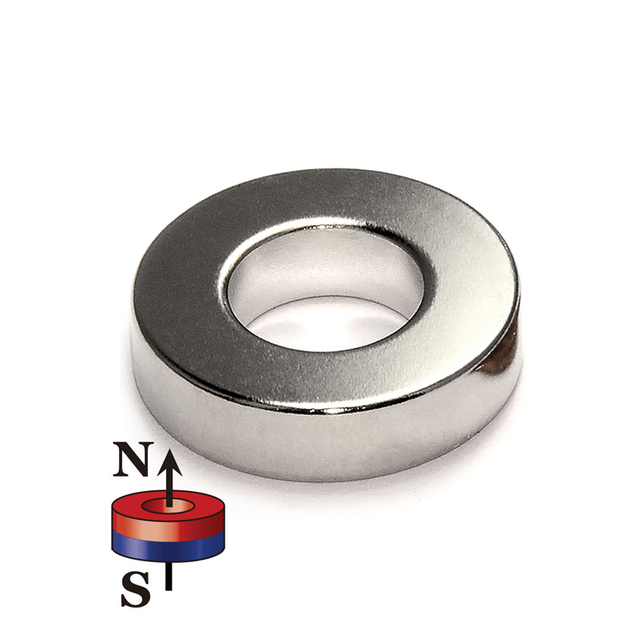

| Product Name | neodymium magnets countersunk hole |

| Material | Neodymium Magnet/Permanet Magnet |

| Size | Various kinds or according to customers' request |

| Shape | Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Or Customized Shapes |

| Grade | N35-N52, N35M-N50M, N33H-N48H, N30SH-N35SH and so on |

| Tolerance in size | +/-0.05 mm |

| Direction of magnetisation | Through the thickness or through the diameter |

| Applications | 1. Electronic areas: speakers, headphones, acoustics, sensors and so on. 2. Motor areas: generators, servo motors, micro-motors, vibration motors, elevator motor and so on. 3. Clean Tech Energy: Water flow enhancement, wind turbines. 4. Health care: MRI, medical treatment equipment. 5. Other industries: electric doors and windows, electric vehicle, electric bicycles, computer, phone, boxes, magnetic tools, notebook and so on |

1.Can neodymium magnets countersunk hole be used in underwater applications?

Our mission is to provide customers with the best solutions for neodymium magnets countersunk hole. Yes, neodymium magnets can be used in underwater applications. However, they must be coated with a protective material such as nickel or epoxy to prevent corrosion.

2.How do neodymium magnets countersunk hole contribute to the transportation industry?

Neodymium magnets are used in a variety of transportation applications, including electric motors, generators, and brakes. They are used in electric vehicles to help reduce the weight of the vehicle and improve its efficiency. They are also used in hybrid and electric vehicles to help reduce the amount of energy needed to power the vehicle. Additionally, neodymium magnets are used in magnetic levitation trains, which use magnetic fields to lift and propel the train.

3.What is the weight-to-strength ratio of neodymium magnets countersunk hole?

The weight-to-strength ratio of Neodymium Magnets is typically around 1:10, meaning that for every gram of weight, the magnet can hold 10 times its weight in force.

4.How are neodymium magnets countersunk hole used in magnetic resonance imaging (MRI)?

Neodymium magnets are used in MRI machines to create a strong magnetic field that is used to align the hydrogen atoms in the body. This alignment allows the MRI machine to detect the signals from the hydrogen atoms and create detailed images of the body. The strong magnetic field also helps to reduce the amount of time it takes to acquire the images.

5.Can neodymium magnets countersunk hole be used in high-temperature environments?

Our neodymium magnets countersunk hole products undergo strict quality control to ensure customer satisfaction. No, neodymium magnets are not suitable for use in high-temperature environments. They can become permanently demagnetized if exposed to temperatures above their Curie temperature, which is typically around 80-200°C (176-392°F).

6.What types of coatings are used on neodymium magnets countersunk hole?

Our mission is to provide customers with the best solutions for neodymium magnets countersunk hole. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

7.How do you prevent neodymium magnets countersunk hole from corroding?

We continuously upgrade our skills and knowledge to adapt to changing neodymium magnets countersunk hole market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

8.About neodymium magnets countersunk hole customization services

Neodymium magnets are a type of rare earth magnet that is made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications, from consumer electronics to industrial machinery. Neodymium magnets can be customized to meet specific requirements, such as size, shape, and strength. Customization services can include machining, coating, and assembly. Customized neodymium magnets can be used in a variety of applications, including motors, sensors, and medical devices.

9.Are neodymium magnets countersunk hole used in electric vehicles?

Yes, neodymium magnets are used in electric vehicles. They are used in the electric motors that power the vehicle, as well as in the batteries that store the energy. Neodymium magnets are also used in the regenerative braking systems of electric vehicles, which help to capture and store energy that would otherwise be lost as heat.

10.Are there any ethical concerns regarding the use of neodymium magnets countersunk hole?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

11.How do neodymium magnets countersunk hole affect electronic devices?

Being one of the top neodymium magnets countersunk hole manufacturers in China, We attach great importance to this detail. Neodymium magnets can affect electronic devices in a variety of ways. They can cause interference with the operation of the device, as the magnetic field can interfere with the operation of the device's internal components. They can also cause physical damage to the device, as the strong magnetic field can cause components to become magnetized and attract each other, potentially damaging the device. Finally, they can cause data loss, as the strong magnetic field can cause data stored on magnetic media to become corrupted or erased.

12.What are the properties of neodymium magnets countersunk hole?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Neodymium magnets are the strongest type of permanent magnet available. 2. They are composed of an alloy of neodymium, iron, and boron. 3. They have a high resistance to demagnetization. 4. They have a high coercivity, meaning they can maintain their magnetic properties even in the presence of other magnetic fields. 5. They have a high energy density, meaning they can generate a strong magnetic field in a small volume. 6. They are brittle and prone to cracking or shattering if dropped or handled improperly. 7. They are susceptible to corrosion if not properly coated.

13.What advancements are being made in the recycling of neodymium magnets countersunk hole?

Recent advancements in the recycling of neodymium magnets include the development of new technologies that allow for the separation of neodymium from other metals in the magnet, such as iron and cobalt. This allows for the recovery of the neodymium for reuse in new magnets. Additionally, new methods of recycling neodymium magnets have been developed that involve crushing the magnets into a powder and then separating the neodymium from the other metals. This powder can then be used to create new magnets.

14.About neodymium magnets countersunk hole MOQ

The minimum order quantity (MOQ) for neodymium magnets varies depending on the supplier. Generally, the MOQ is between 1 and 10 pieces, but some suppliers may require a higher MOQ.

15.How do you recycle neodymium magnets countersunk hole?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

16.What is the maximum operating temperature of neodymium magnets countersunk hole?

We continuously upgrade our skills and knowledge to adapt to changing neodymium magnets countersunk hole market needs. The maximum operating temperature of Neodymium Magnets is 80°C (176°F).

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.