| Availability: | |

|---|---|

| Quantity: | |

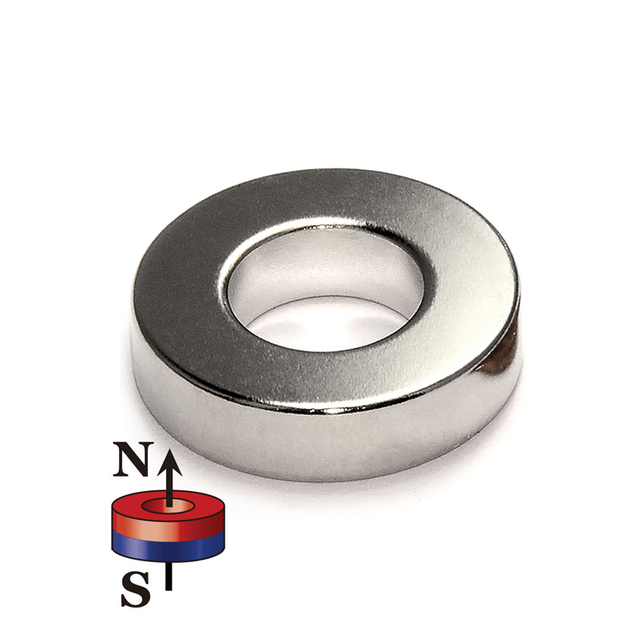

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~93℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | strontium magnet vs. neodymium | Package | customized |

| Shape | Hexagon strontium magnet vs. neodymium | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.Are there any ethical concerns regarding the use of strontium magnet vs. neodymium?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

2.What is the manufacturing process for strontium magnet vs. neodymium?

Our strontium magnet vs. neodymium products undergo strict quality control to ensure customer satisfaction. 1. Raw Material Preparation: Neodymium magnets are made from an alloy of neodymium, iron, and boron. The raw materials are melted together in a vacuum induction furnace to create a homogenous alloy. 2. Compacting: The molten alloy is then poured into a die and compacted under high pressure to form a solid block. 3. Sintering: The compacted block is then heated in a vacuum furnace to sinter the material, which increases its strength and magnetic properties. 4. Machining: The sintered block is then machined into the desired shape and size. 5. Magnetizing: The machined magnet is then magnetized by exposing it to a strong magnetic field. This process aligns the magnetic domains within the material, creating a permanent magnet.

3.How do strontium magnet vs. neodymium work?

We have established a good reputation and reliable partnerships within the strontium magnet vs. neodymium industry. Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications. Neodymium magnets work by creating a strong magnetic field that attracts ferromagnetic materials, such as iron, nickel, and cobalt. The magnetic field is created when the electrons in the atoms of the neodymium alloy align in the same direction. This alignment creates a strong magnetic field that can attract ferromagnetic materials from a distance.

4.How do you recycle strontium magnet vs. neodymium?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

5.How do strontium magnet vs. neodymium contribute to the aerospace industry?

Neodymium magnets are used in a variety of aerospace applications, including in electric motors, actuators, and sensors. They are also used in navigation systems, guidance systems, and propulsion systems. Neodymium magnets are highly resistant to corrosion and can withstand extreme temperatures, making them ideal for use in aerospace applications. Additionally, their high magnetic strength makes them ideal for use in motors and actuators, allowing for more efficient operation and greater power output.

6.What role do strontium magnet vs. neodymium play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

7.What are strontium magnet vs. neodymium?

As one of the strontium magnet vs. neodymium market leaders, we are known for innovation and reliability. Neodymium magnets are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications, including motors, generators, hard drives, and loudspeakers.

8.How do you store strontium magnet vs. neodymium?

Neodymium magnets should be stored in a dry, temperature-controlled environment away from other magnets or magnetic materials. They should also be stored away from moisture, heat, and direct sunlight. It is also important to keep them away from any ferrous materials, as these can cause the magnets to become magnetized and attract each other.

9.Can strontium magnet vs. neodymium lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

10.How are strontium magnet vs. neodymium used in the military?

Neodymium magnets are used in the military for a variety of applications. They are used in navigation systems, guidance systems, and sensors. They are also used in weapons systems, such as magnetic mines, and in the guidance systems of missiles and torpedoes. Neodymium magnets are also used in the construction of military vehicles, such as tanks and aircraft, to reduce their weight and improve their performance.

11.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

12.How do you prevent strontium magnet vs. neodymium from corroding?

We continuously upgrade our skills and knowledge to adapt to changing strontium magnet vs. neodymium market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

13.How do strontium magnet vs. neodymium contribute to renewable energy storage?

Neodymium magnets are used in a variety of renewable energy storage systems, such as flywheels, supercapacitors, and batteries. Flywheels use the magnets to store energy in the form of kinetic energy, while supercapacitors use them to store energy in the form of electrical charge. Batteries use the magnets to store energy in the form of chemical energy. Neodymium magnets are also used in electric motors and generators, which are essential components of renewable energy systems.

14.What types of coatings are used on strontium magnet vs. neodymium?

Our mission is to provide customers with the best solutions for strontium magnet vs. neodymium. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

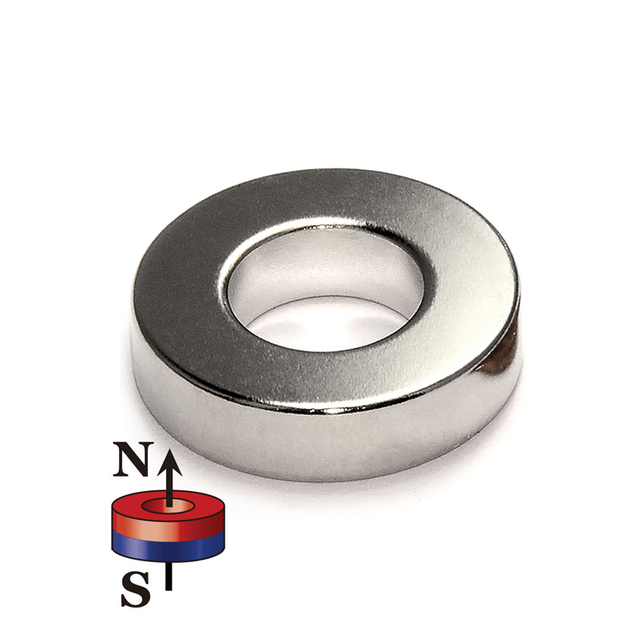

| Place of Origin | China | Certification | ISO 9001: 2015 ROHS REACH |

| Brand Name | Honesun | Tolerance | 0.05mm |

| Model Number | Others, customized | Working Temperature | -40℃~93℃ |

| Type | Permanent | Delivery time | 3-15days |

| Composite | strontium magnet vs. neodymium | Package | customized |

| Shape | Hexagon strontium magnet vs. neodymium | Sample | Avaliable |

| Application | Industrial Magnet | Keyword | neodymium magnet |

| Processing Service | Cutting, Punching | Quality Control | ≥98% |

| Grade | N35-N52 | Packaging Details | 1:Standard air and vessel package 2:according to customers's request |

| Coating | Epoxy.Black Epoxy. Nickel.Silver.etc | Lead time (days) | To be negotiated |

1.Are there any ethical concerns regarding the use of strontium magnet vs. neodymium?

Yes, there are ethical concerns regarding the use of Neodymium Magnets. Neodymium magnets are powerful and can cause serious injury if swallowed. They can also interfere with medical devices such as pacemakers and defibrillators. Additionally, Neodymium magnets can be dangerous if used in the wrong way, such as when used to create a powerful magnetic field. Finally, Neodymium magnets can be hazardous to the environment if not disposed of properly.

2.What is the manufacturing process for strontium magnet vs. neodymium?

Our strontium magnet vs. neodymium products undergo strict quality control to ensure customer satisfaction. 1. Raw Material Preparation: Neodymium magnets are made from an alloy of neodymium, iron, and boron. The raw materials are melted together in a vacuum induction furnace to create a homogenous alloy. 2. Compacting: The molten alloy is then poured into a die and compacted under high pressure to form a solid block. 3. Sintering: The compacted block is then heated in a vacuum furnace to sinter the material, which increases its strength and magnetic properties. 4. Machining: The sintered block is then machined into the desired shape and size. 5. Magnetizing: The machined magnet is then magnetized by exposing it to a strong magnetic field. This process aligns the magnetic domains within the material, creating a permanent magnet.

3.How do strontium magnet vs. neodymium work?

We have established a good reputation and reliable partnerships within the strontium magnet vs. neodymium industry. Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet available and are used in a variety of applications. Neodymium magnets work by creating a strong magnetic field that attracts ferromagnetic materials, such as iron, nickel, and cobalt. The magnetic field is created when the electrons in the atoms of the neodymium alloy align in the same direction. This alignment creates a strong magnetic field that can attract ferromagnetic materials from a distance.

4.How do you recycle strontium magnet vs. neodymium?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are not typically recycled, as they are made from rare earth metals and are difficult to separate and process. It is best to reuse them or donate them to a local school or organization that can use them.

5.How do strontium magnet vs. neodymium contribute to the aerospace industry?

Neodymium magnets are used in a variety of aerospace applications, including in electric motors, actuators, and sensors. They are also used in navigation systems, guidance systems, and propulsion systems. Neodymium magnets are highly resistant to corrosion and can withstand extreme temperatures, making them ideal for use in aerospace applications. Additionally, their high magnetic strength makes them ideal for use in motors and actuators, allowing for more efficient operation and greater power output.

6.What role do strontium magnet vs. neodymium play in magnetic levitation technology?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. Neodymium magnets are used in magnetic levitation technology to create a strong magnetic field that can suspend an object in mid-air. The magnets are arranged in a specific pattern to create a stable magnetic field that can support the weight of the object. The magnets are also used to control the movement of the object, allowing it to move in a specific direction or remain stationary.

7.What are strontium magnet vs. neodymium?

As one of the strontium magnet vs. neodymium market leaders, we are known for innovation and reliability. Neodymium magnets are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron. They are the strongest type of permanent magnet commercially available and are used in a wide variety of applications, including motors, generators, hard drives, and loudspeakers.

8.How do you store strontium magnet vs. neodymium?

Neodymium magnets should be stored in a dry, temperature-controlled environment away from other magnets or magnetic materials. They should also be stored away from moisture, heat, and direct sunlight. It is also important to keep them away from any ferrous materials, as these can cause the magnets to become magnetized and attract each other.

9.Can strontium magnet vs. neodymium lose their magnetism over time?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. Yes, neodymium magnets can lose their magnetism over time. This is due to a process called demagnetization, which occurs when the magnet is exposed to high temperatures, strong electrical currents, or other magnets.

10.How are strontium magnet vs. neodymium used in the military?

Neodymium magnets are used in the military for a variety of applications. They are used in navigation systems, guidance systems, and sensors. They are also used in weapons systems, such as magnetic mines, and in the guidance systems of missiles and torpedoes. Neodymium magnets are also used in the construction of military vehicles, such as tanks and aircraft, to reduce their weight and improve their performance.

11.What are the environmental impacts of mining Neodymium for magnets?

The environmental impacts of mining neodymium for magnets can include air and water pollution, land degradation, and the destruction of habitats. Mining neodymium can also lead to the release of hazardous chemicals, such as sulfur dioxide, nitrogen oxides, and carbon dioxide, into the atmosphere. Additionally, the mining process can cause soil erosion, which can lead to the destruction of vegetation and wildlife habitats. Finally, the mining process can also lead to the release of radioactive materials, which can be hazardous to human health.

12.How do you prevent strontium magnet vs. neodymium from corroding?

We continuously upgrade our skills and knowledge to adapt to changing strontium magnet vs. neodymium market needs. Neodymium magnets can be protected from corrosion by coating them with a thin layer of oil, wax, or lacquer. Additionally, they can be stored in a dry, low-humidity environment.

13.How do strontium magnet vs. neodymium contribute to renewable energy storage?

Neodymium magnets are used in a variety of renewable energy storage systems, such as flywheels, supercapacitors, and batteries. Flywheels use the magnets to store energy in the form of kinetic energy, while supercapacitors use them to store energy in the form of electrical charge. Batteries use the magnets to store energy in the form of chemical energy. Neodymium magnets are also used in electric motors and generators, which are essential components of renewable energy systems.

14.What types of coatings are used on strontium magnet vs. neodymium?

Our mission is to provide customers with the best solutions for strontium magnet vs. neodymium. Neodymium magnets are typically coated with a protective layer of nickel, copper, or zinc. Nickel plating provides the best corrosion resistance, while copper plating provides the best electrical conductivity. Zinc plating is the most economical option and provides good corrosion resistance.

Honesun Industrial Co., Ltd. focuses on designing, researching, developing, manufacturing and selling Magnets and Magnetic Assemblies. With more than 15 years' rich experience and considerate services.we have been recognized as a reliable.